Managing facilities effectively is mission-critical for every industry, but nowhere is this more evident than in the life sciences industry. To profitably produce pharmaceutical products of consistent quality, life sciences facilities must adhere to a strict set of guidelines, regulations, and performance expectations, ultimately driving the cost of pharma products down and delivering quality products to patients faster.

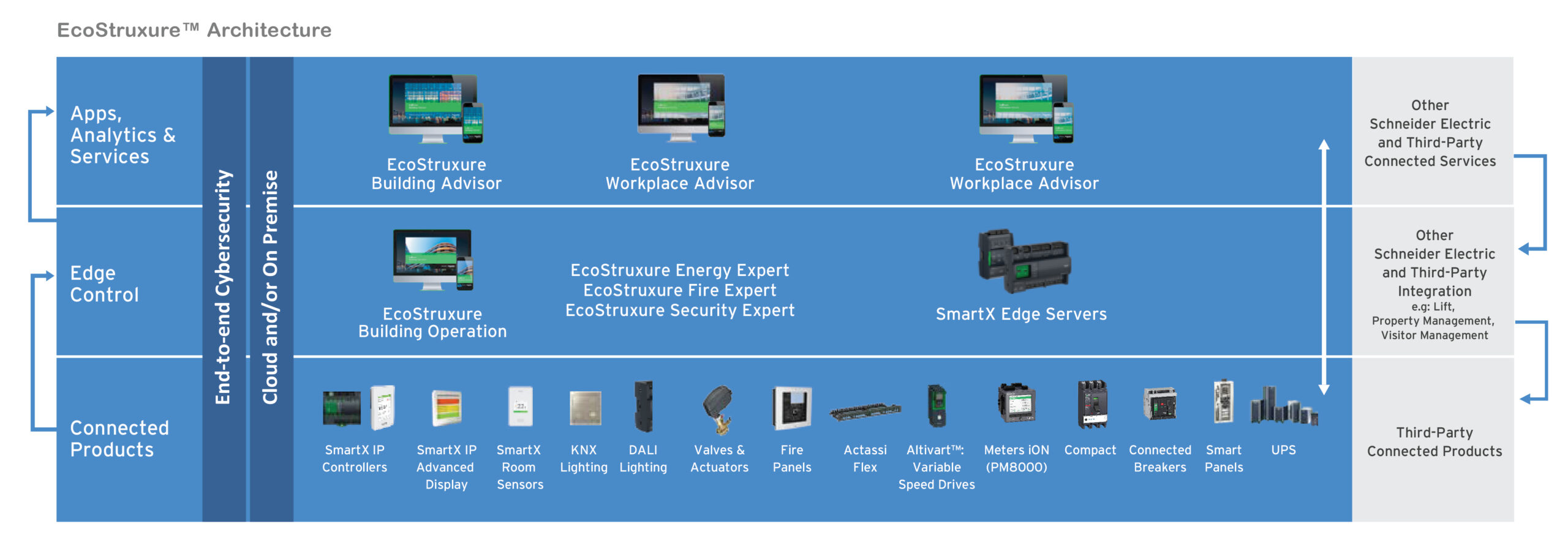

And, it is here that Schneider Electric’s EcoStruxure platform shines. EcoStruxure provides much more than building automation. The platform also delivers superior environmental control to ensure that the production environment complies with requirements and regulations. And, it addresses power safety and availability needs, such as standardization, site assessment, and predictive maintenance for electrical distribution.

As illustrated by the below case studies, the many benefits of EcoStruxure for the Life Sciences Industry include:

- Minimize costly deviations, lost product and unplanned downtime

- Manage vast data from multiple siloed systems, suppliers and sites

- Ease adherence to regulatory requirements and good practices

- Evolve existing and build a new facility to rapidly meet rising demand

- Mitigate risk to IP theft from cyber attacks

- Accomplish sustainability goals to increase shareholder value

Case Study: Becton Dickinson, France

Customer challenge

- Need of an innovative solution enabling the diagnostic and maintenance of a syringe manufacturing machine

- Improve production machines performance to ensure quality of the product

The Solution

- EcoStruxure Augmented Operator Advisor

Customer benefits

- Real-time visualization of all points of interest

- Contactless maintenance increasing operator safety

- Capitalize know-how in order to share with knowledge with all operators

- Efficient robust system for operations and better monitoring of production and ensure continuity of production with consistent quality

- Solution easy to integrate to existing machine

Case Study: CVC Technologies, Taiwan

Customer challenges

To fully digitize their pharmaceutical liquid filling and capping machines with:

- Safer equipment

- Digital maintenance capabilities

- Visibility into machine status from anywhere at any time

The solution

CVC chose a complete EcoStruxure Machine solution, including digital services, because, unlike

the competition, we could offer a full end-to-end IoT solution with strong technical support.

Customer benefits

- 30% faster commissioning

- Faster and more efficient maintenance, quality control and troubleshooting through real-time visibility into a machine’s status

- Improved safety and reduced human error by digitizing maintenance manuals

- Improved customer service to end user

Case Study: Liaoning Chunguang Pharmaceutical Equipment Corporation, China

Customer challenges

- Improve data traceability

- Improve machine performance, stability, and manufacturing capability

- Increase machine intelligence

- Accelerate R&D of new models to the market

The solution

Chunguang selected a full EcoStruxure Machine solution, including the digital services of EcoStruxure

Machine Advisor, to digitize their pharmaceutical packaging machines.

Customer Benefits

- 50% reduction in energy consumption and costs

- 50% less downtime for higher production efficiency

- 50% faster commissioning time

- 50% less operating costs